Live, neutral, earth – is it that simple?

Low voltage electrical distribution systems commonly found in domestic settings, which adhere to appropriate electrical installation guidelines, probably include live, neutral and earth circuits. But is it as straight forward as it looks?

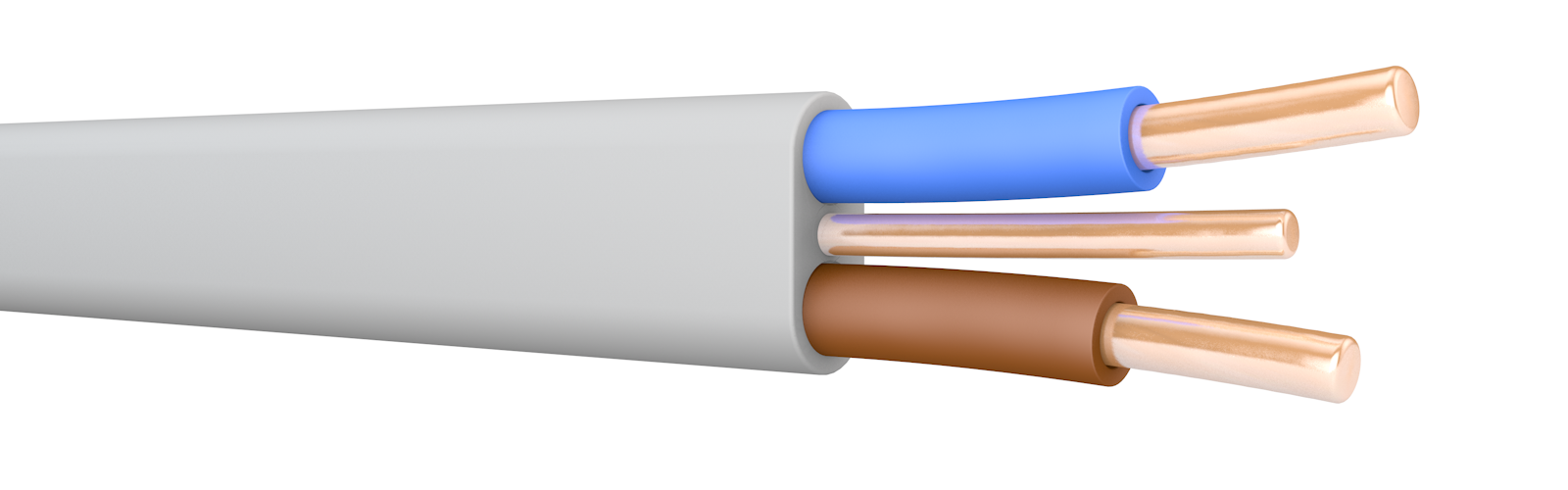

What is live, neutral and earth – the key components of a cable

The live core, or the phase conductor is normally required to have brown coloured insulation or marked as brown if a different colour. The neutral core acts as the return path for current and completes the circuit, these are expected to be blue in colour, or marked as blue. The circuit protective conductor (CPC) is designed to carry a fault current should one occur and in turn is connected to the circuit protection devices. The CPC may or may not be insulated depending upon the system design, but we commonly see CPC earth conductors insulated with two colours, normally green and yellow.

Single-phase electricity

Single-phase circuits use the live and neutral. The live carries current or load, and the neutral core provides a path for the return current. Most residential homes require single-phase supply only because they require small amounts of power for applications such as domestic lighting and heating circuits. Single-phase common voltage starts at 230V with a possible spread of up to 254V and the oscillation frequency approximates to 50Hz – 50 cycles per second.

PVC or XLPE insulation?

Cables, no matter in what application, need electrical insulation. In the past, this has been paper wrapped around the conductor and for HV overhead lines the insulation is still in the air! The most common electrical insulation today is however PVC (Polyvinyl Chloride). It is an excellent material that when mixed or compounded correctly with right ingredients by experts, provides effective electrical and physical protection. For example, it is ideal for insulating and sheathing Prysmian “twin and earth” cable. The insulation isolates and prevents direct contact between conductors, and between a conductor and its environment. However, if a higher conductor temperature is required, then consider using cables insulated with XLPE instead.

PVC and LSOH sheath

The cable’s sheath is also important. This is the outer extruded material that holds all of the inner parts together. PVC is the most common sheath type for a number of reasons. It’s readily available, easy to manufacture and handle, and the cable is typically more pliable, especially at lower temperatures. However, in the event of fire in a building such as a shopping centre or a hospital, PVC burns and produces thick black smoke, hydrochloric acid, and other toxic gases, which is a risk to public health and emergency equipment.

Prysmian 6242Y

Prysmian 6242B

The Prysmian 6242B cable is similar in construction to the 6242Y but has a white LSOH sheath and XPLE insulation. In the event of a fire, it will emit extremely low levels of smoke and toxic gases. The cable is a twin core Low Smoke, Zero Halogen (LSOH) cable designed for indoor installation methods including clipped direct, on tray or in basket and buried within plaster or embedded in walls.

FP200 GOLD

In short, when it comes to low voltage electrical distribution systems, it’s not as simple as just saying live, neutral and earth. Although CPC is commonly insulated with two colours (usually yellow and green) it may or may not be insulated – it depends on the system design. PVC is the most common sheath type as it’s readily available, pliable, easy to manufacture and handle, but for higher conductor temperatures, consider XLPE. When it comes to fire safety, FP200 GOLD features a tough Insudite® insulation which is ideal for fire alarms and fire detection systems.

The Power of Prysmian

What sets apart? The electrical industry has counted on us for over a century to deliver products that perform. Our heritage and dedication give you the tools and assurance to get the job done.